Improving the Management of Technical Information

- Raimund Laqua

- Jun 8, 2017

- 3 min read

Compliance programs depend on up to date technical information to support each process. This information includes such things as: process safety information, drawings, operating limits, set points, performance standards, equipment data, permits, quality records, procedures, calculations, risk analysis, and collected measurements. When this information is difficult to find, not available, or out of date this can lead to wrong decisions that impact the safe operations of the facility or at a minimum, create waste.

Technical information is needed by many roles within an organization including:

operators, to understand how to safely operate the facility

asset owners, to determine if changes are replacement in kind or not

maintenance, to know how to properly maintain equipment

engineers, to understand how best to replace or improve processes

safety specialists, to identify risk

management, to assess compliance and performance

Even with the importance that technical information has, it is not unusual to find that a significant amount of this information is not readily available and sometimes not available at all. The reasons for why this is case varies from company to company. However, there are some common themes as to why technical information is not easily found:

It takes too long to find the information

Knowledge of where information is stored resides with people that have left the company

Information is stored in silos and not easily discovered or accessed

Every system has its own way storing and finding information

Information management processes and practices are inadequate

Information systems have become unsustainable and cannot keep up

There is no single role in the organization that is accountable for the management and use of technical information.

These issues pose a significant challenge not only to the safe operations of facilities, but also to maintaining and operating processes as efficiently as possible. There is a lot of wasted time spent looking for information that is not necessary. Some analysts report that this can be as much as 20% of a person's day.

The good news is that it is possible to improve how technical information is managed through relatively small improvements often using the technologies that are already in place within organizations.

Conducting an information and systems audit is the first place to start. When making improvements, it is necessary to know the condition of your current processes and systems. An important outcome of an audit is the identification of what information is critical. This will help prioritize what improvements should happen first.

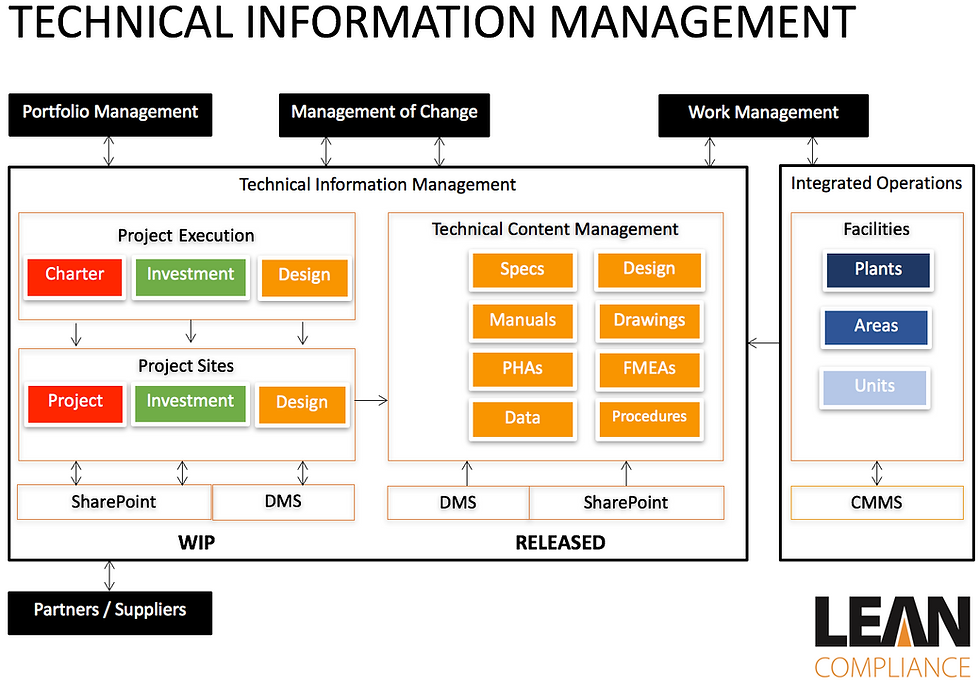

Another important step is to understand the architecture and flow of information across the organization. Technical information has a particular flow and it is important that the right system is being used at the right place in the value chain. At a basic level, information is created during the execution of capital or maintenance projects, and then released to maintenance and operations. The following diagram can help visualize the flow of information across key systems and processes:

The transition between each stage in the information flow can be a point of weakness in the overall system. So focusing on the system boundaries may help to significantly reduce information loss and improve reliable access to technical information.

Improving the management of technical information is crucial and should be part of every operational excellence program. With knowledge and expertise walking out the door, as an aging workforce retires and the workforce is reduced, companies can no longer lean on the assumption that someone will know where the information is and that the information is up to date. Instead, companies need to improve their technical information management systems and processes to ensure that compliance and operating decisions are made with the right information, in a format that is understood, and at the time it is needed.

Plan-Do-Check-Act Questions:

What ways would your compliance programs improve if information was more readily available?

What issues have you observed that hinder access to safety-critical information?

Is the original design basis for process and equipment available to make replacement in kind determinations? If not then how can this be improved?

What is your next target condition that you can begin taking steps towards?