Double Your Capacity to Deliver Total Value

- Raimund Laqua

- Aug 6, 2025

- 2 min read

Updated: Aug 7, 2025

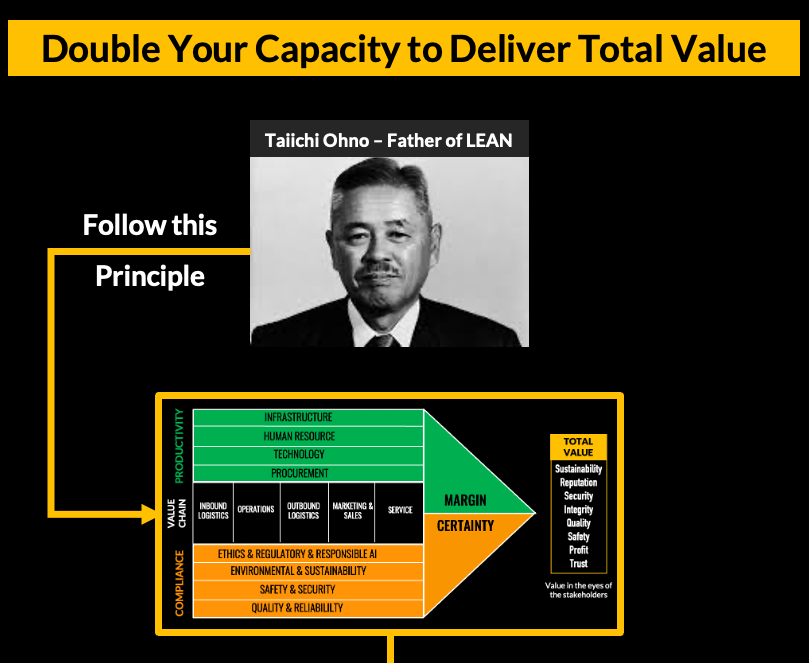

Taiichi Ohno's Secret to Delivering Total Value

To understand this approach, we need to return to the origins of LEAN manufacturing when Taiichi Ohno first introduced it at Toyota in the 1950s. While Ohno is widely known as the father of LEAN who taught waste removal, standard work, and continuous flow, there's a crucial element of his approach that often gets overlooked.

Ohno's transformational insight (not really a secret) was that the production leader should "break" the standard by continuously improving it. When you achieve an improvement that allows you to remove your best person from the production line, what that person does next becomes the key to exponential growth rather than incremental gains.

These freed-up resources didn't disappear—they worked on creating further improvements that resulted in even more people being removed from the line. Through this compounding effect, Ohno eventually had enough people to start an entire second production line.

Instead of achieving fractional improvements, he was able to double his capacity using existing resources.

As Ohno explained: "Making an improvement that can take one person out results in just one person's cost being saved. If you take that person and have her make improvements, you start getting savings of two, three, four, and five people and so forth. Taking out the best person and making her improve the rest is really effective."

This same principle applies to creating Total Value through productivity and compliance programs. You begin by reducing waste, standardizing work, and streamlining workflow—but that's only the foundation of what's possible.

The real transformation happens when freed-up resources from reactive, unproductive activities are redirected toward proactive, productive work. These resources can then anticipate changes, address root causes, and introduce new capabilities that keep the organization ahead of risk, operating between the lines, and staying on-mission.

By following this approach, organizations can double their capacity to meet not just regulatory obligations, but all their obligations—using the resources they already have.

The capacity for dramatic improvement often already exists within organizations; it simply requires a more holistic approach to unlock it.