You can't turn lagging into leading indicators no matter how hard you try

- Raimund Laqua

- Mar 20, 2019

- 2 min read

Updated: Feb 15, 2024

The Challenge

Counting near misses, incidents, defects, violations, and other non-conformance is of value and necessary as part of prescriptive: regulation, industry standards, and internal policies.

However, when it comes to complying with performance and outcome-based commitments where the goal is to achieve zero fatalities, zero explosions, zero violations, and zero defects then you need a risk-based process that uses proactive actions informed by both lagging and leading indicators.

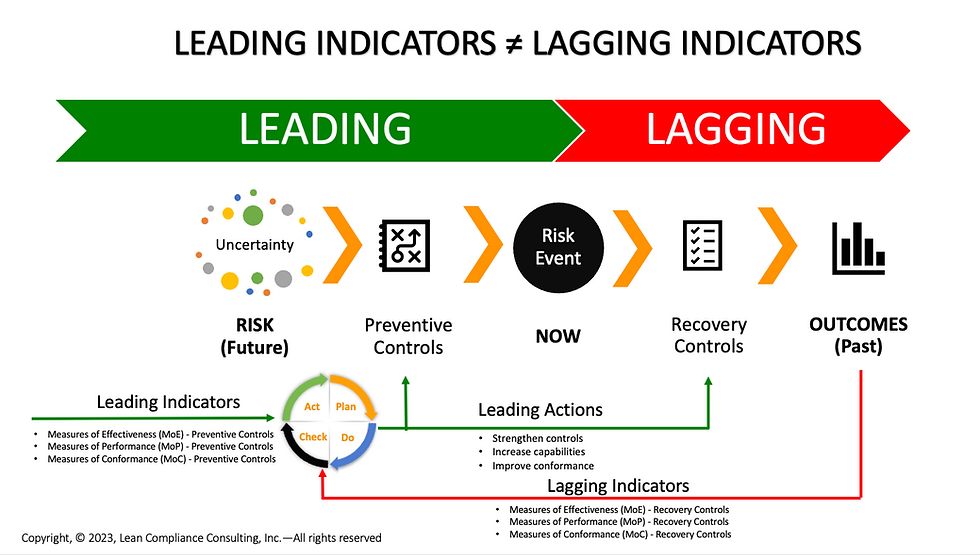

While many companies are rich in lagging indicators they are poor in leading indicators. To address this, many attempt to turn lagging indicators into leading indicators which is not possible no matter how hard you try. Although, with proactive oversight you can turn lagging indicators into leading actions (more on this later).

Many organizations try to use measures of conformance to predict and possibly prevent future occurrences. However, lagging indicators of this kind can never distinguish between whether your risk controls are effective or if you were just "lucky". They are also too late to prevent what has already occurred and for those looking to improve safety, quality, environmental, or regulatory outcomes this is a big deal.

Lagging Indicators and Actions

Lagging indicators measure what has already happened specifically after a risk event has occurred.

Lagging indicators are always retrospective, too late, and of no value with respect to the past events.

Lagging indicators are still beneficial as they help to identify failure modes or vulnerabilities albeit after the fact. This data can in turn be used to initiate actions to mitigate the effects of the adverse event, which is considered as a corrective and lagging action.

Lagging indicators can also be used to strengthen control processes to prevent re-occurrence of the unwanted event or mitigate its effects. This is a preventive action and leading with respect to future risk.

Leading Indicators and Actions

Leading indicators, on the other hand, are derived from the control processes that are in place to prevent unwanted events before they happen. They are on the left side of the bowtie diagram and before the risk event.

Leading indicators include measures of effectiveness of the preventive controls which are predictive in terms of the likelihood of a given risk event. Leading indicators must have predictive power to be considered effective. The effectiveness of controls contributes to the probability of occurrence of the risk event.

Leading actions are steps taken to improve the effectiveness of both preventive and mitigative controls to improve the level of protection to achieve an acceptable level of risk which is the purpose of risk management and the standard for overall compliance effectiveness.

Bottom Line

Lagging indicators can never be leading as they measure things after the risk event. They may have utility to predict future risk events but this is limited as they often measure things related to symptoms not the root cause.

The best leading indicators are those that have predictive utility and connected to preventive controls. This information provides advance warning of a possible risk event and an opportunity to do something about it.

Consider joining The Proactive Certainty Program where we help you develop operational leading and lagging indicators (among other things) for your compliance programs.